Electrical wiring that is buried in the ground or otherwise exposed to soil, moisture, physical impact, and varying climatic conditions requires more than just regular cables. Cable selection is crucial for safety, durability, and long-term performance regardless of it being outdoor lighting, industrial machinery, residential buildings, or major infrastructure. SWA cables are among the most dependable underground and outdoor electrical installation cable options.

Steel Wire Armoured (SWA) cables are made to resist extreme environmental conditions while at the same time providing continuous power transmission. Their sturdy construction, great mechanical strength, and versatility have earned them favour in the residential, commercial, and industrial sectors. Let's discuss with the help of SWA Cable Suppliers about the reasons why SWA cables are perfect for underground and outdoor applications and why they are a reliable investment for current electrical installation needs.

What are SWA Cables?

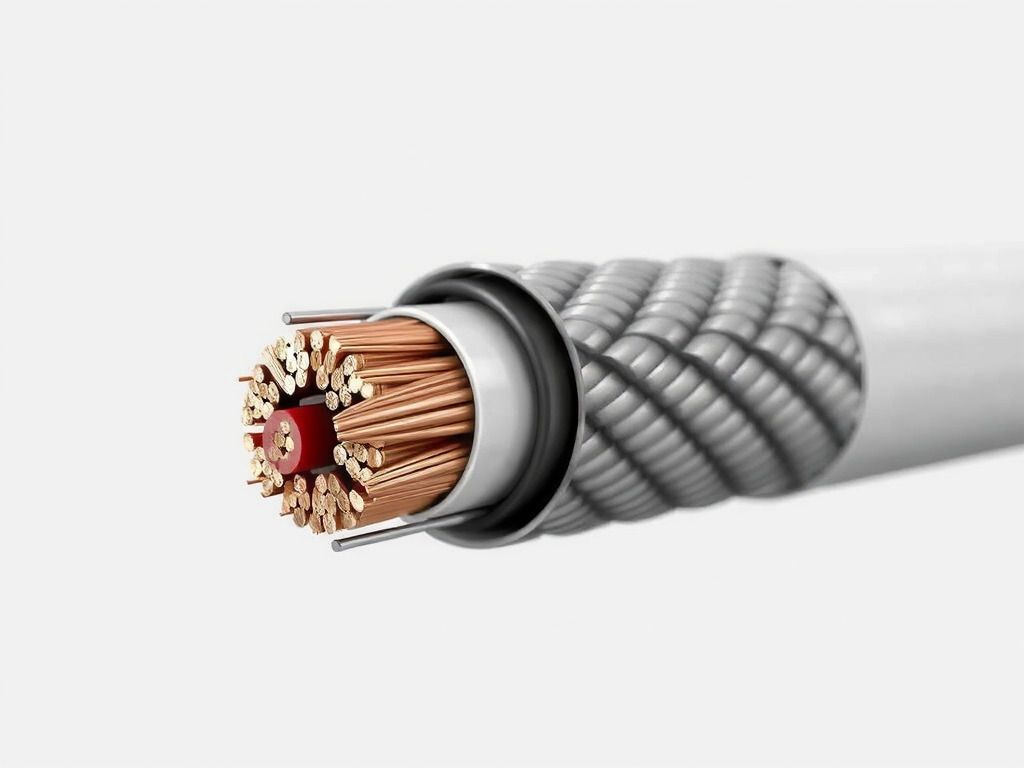

SWA cables are electrical power cables that have been provided with a steel wire armour layer that shields the inner conductors from damage. The armoring serves as an external protective barrier that helps the cable withstand impacts, pressure, rodents, and harsh weather conditions.

A standard SWA cable is made up of:

- Conductors (generally copper or aluminium)

- Insulation layer to ensure electrical safety

- Bedding layer that provides structural support

- Steel wire armour to give mechanical protection

- Outer sheath to protect from environmental factors

With this multi-layer design, SWA cables are capable of operating effectively even when the usual cables would either fail or get easily damaged.

Enhanced Mechanical Protection for Underground Use

Among the several benefits that SWA cables provide, their strong resistance to mechanical injuries is the most notable one when it comes to underground applications. Cables buried underground are at risk of being damaged by factors such as soil pressure, inadvertent excavation, vibration, and movement over time.

The wire-armoured steel:

- Protects the cable against crushing and compression

- Offers resistance to sharp objects and debris

- Lowers the chances of damage during installation and maintenance

This is why SWA cables, as per SWA Cable Manufacturers, are often used without the need for additional protective ducts, as they can be buried directly in the ground. Therefore, the installation becomes safe and less expensive over time.

Enhanced Safety in Outdoor Environments

Outdoor electrical installations are consistently exposed to various weather changes such as rain, heat, humidity, and UV radiation. SWA cables can handle these conditions without losing their electrical features.

Main safety features are:

- Extremely sealed against moisture

- Outer sheath is very tough and resists insulation damage

- Less chance of electrical faults from environmental exposure

Thus, SWA cables are suitable for the lighting of the outside environment and the electrification of the garden, parking areas, and open-air industrial facilities where safety and reliability are very important.

Long-Term Durability and Reliability

When cables are buried underground or set up outdoors, it is not easy to gain access around them and any repairs become very expensive and troublesome. SWA cables are designed with durability in mind; they remain efficient for a very long time without requiring much maintenance.

Their strength leads to:

- Smaller percentage of operational failures than the unarmoured type of cables

- Less checking or replacing at short intervals

- Steady energy supply even during heavy usage

Their extended lifetime thus helps to minimize operational downtimes as well as save costs in the long run for the infrastructure and industrial facilities.

Excellent Resistance to Environmental Stress

Outdoor as well as underground cable systems can face environmental stress, which is a big issue. Temperature changes, soil chemical properties, and moisture levels are some of the factors that heavily influence the performance of cables.

SWA cables can counteract:

- Corrosion resulting from wet soil

- Temperature stress that varies with the seasons

- Chemical contact in industrial as well as coastal areas

Thanks to such a high resistance, these cables can maintain good insulation as well as electrical efficiency even in severe environments; thus, they can be used for urban but also for very remote locations.

Added Electrical Protection and Earthing Benefits

Apart from the physical strength, the steel wire armour present in the SWA cables may also be used in an electrical way. The armour in numerous installations is capable of serving as an earth continuity conductor, thereby improving the overall safety of the system.

This can give you:

- More efficient protection against faults

- Quicker identification and separation of faults

- Better compliance with electrical safety standards

With such internal safety features, it is very advantageous to use SWA cables in settings where electrical risk management is a top concern, such as commercial and industrial environments.

Versatility Across Multiple Applications

The use of SWA cables is not restricted to one kind of installation only. Thanks to their versatile nature, they can be used for a variety of underground and outdoor applications, such as:

- Power distribution networks

- Industrial plants and factories

- Residential housing projects

- Outdoor lighting and street infrastructure

- Agricultural and utility installations

Because of this versatility, engineers and contractors can standardize the choice of cables on different projects, thus making the processes of design, procurement, and installation much easier.

Compliance with Industry Standards

Electrical works have to adhere to quite stringent regulations and safety requirements and this is even more so the case with underground and outdoor installations. SWA cables comply with the standards of the recognized industry and therefore meet the criteria for reliability and regulatory approval.

The following are some of the benefits of compliance:

- Safe operation within the limits of the specified load

- Compatibility with modern electrical systems

- Peace of mind for engineers, contractors, and end users

Employing compliant SWA cables eliminates the risk of expensive changes or retrofits needed because of non-compliance with the regulations.

Conclusion

Choosing the correct type of cable plays a crucial role in the safety, efficiency, and durability of underground as well as external electrical systems. Due to their excellent mechanical shielding, resistance to the elements, and dependable performance over time, SWA cables are indisputably the best option.

The combination of increased safety and durability, cost savings, and meeting of regulatory standards makes SWA cables a comprehensive offering for challenging installation environments. Thanks to their well-established effectiveness in various industries, they are a dependable option for engineers, contractors, and project managers aiming to establish reliable electrical infrastructures.

In locations where there is always pressure from failure and limited access, SWA cables provide the power, safety, and reliability necessary to operate underground as well as outdoor systems efficiently.